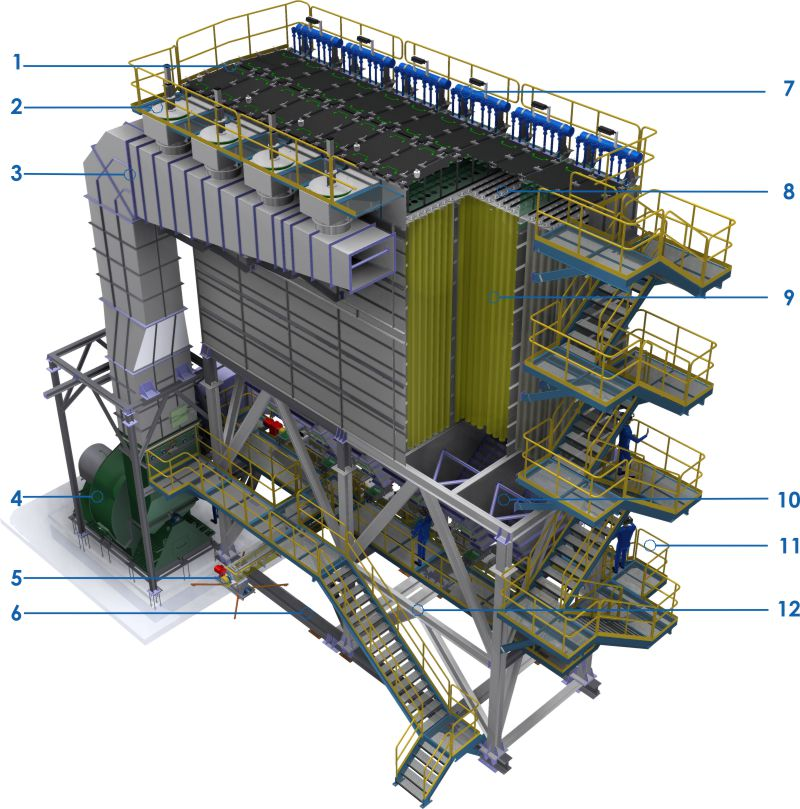

In the development of this product, Ingemol has focused its practice and experience on the design, manufacture and assembly of systems for environmental control in cement, concrete, asphalt, steel, foundries, steel mills and in any type of processes where pollution is generated.

Specialists in the manufacture of jet-pulse bag filters, being the most reliable systems on the market with efficiencies of up to 99.95%

With this equipment we guarantee that the exhaust air complies with all the regulations of the regulations for projection and air quality control, of the Ministry of the Environment and international rules.

With the proper selection of filter materials and technical components, the operation of the equipment is more efficient, its maintenance is cheaper and the durability of the equipment is greater.

General description

The jet pulse On Line self-cleaning bag filter, designed and supplied by INGEMOL SA, is a continuous cleaning system, with the capacity to extract dust particles as small as submicrons from contaminated air flows.

Among dust cleaning solutions, the bag filter is the most efficient known to date and in some cases operates with collection efficiency of 99.99%, which allows compliance with local environmental control standards.

Main Features

Main Parts

sleeve holder sheet

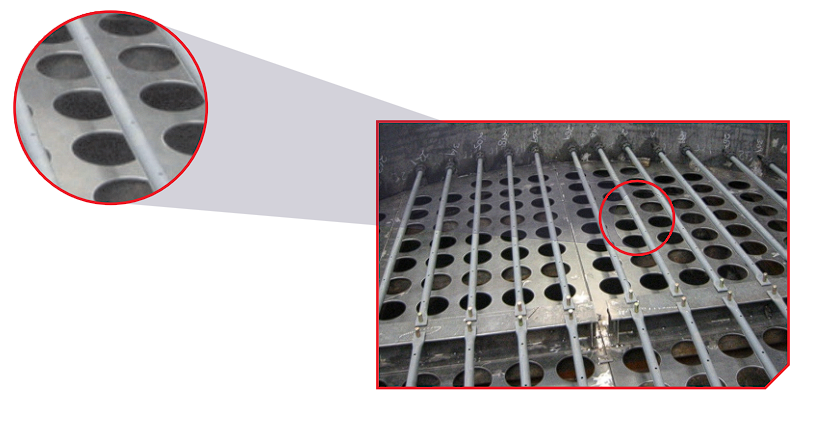

The sleeve holder sheet

(tubesheet or cell plate) is made of 1/4” A36 steel sheet with

high precision cold perforations, to accommodate the sleeves and

reinforced with a 3” x ¼” plate, mounted on a structure. metal

capable of supporting the weight of the basket-sleeve assembly, without suffering

any deformation.

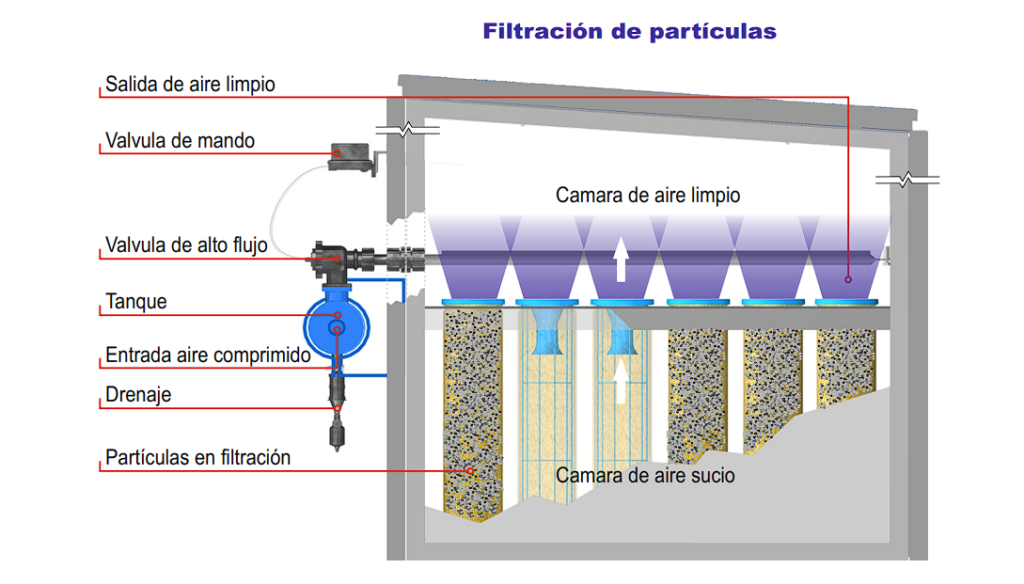

Pulmon tanks with valves

Lung tanks serve as compressed air accumulators.

Pulse valves, mounting bases, solenoid and purge valves and other compressed air equipment are placed in this tank.

It is made of structural steel pipe, with wall of 7 mm. Y

previously tested, to ensure its performance in operation and the

exhaust from compressed air When the high flow valve opens, high pressure air is fired,allowing the sleeves to be cleaned.

.

High Flow Valves

These double diaphragm valves have been specifically designed

to handle larger volumes of compressed air, more effectively

than single diaphragm valves with air intake greater than

output, creating a venturi effect, inducing high air velocity; With

this effectiveness, a reduction is achieved in the number of times the valve

has to be triggered in order to clean, saving compressed air and

prolonging the useful life of the sleeves.

Multivalve boxes

They control the operation of the high flow valves through

an air connection that allows them to open and close, according

to the signals emitted by the electronic programmer

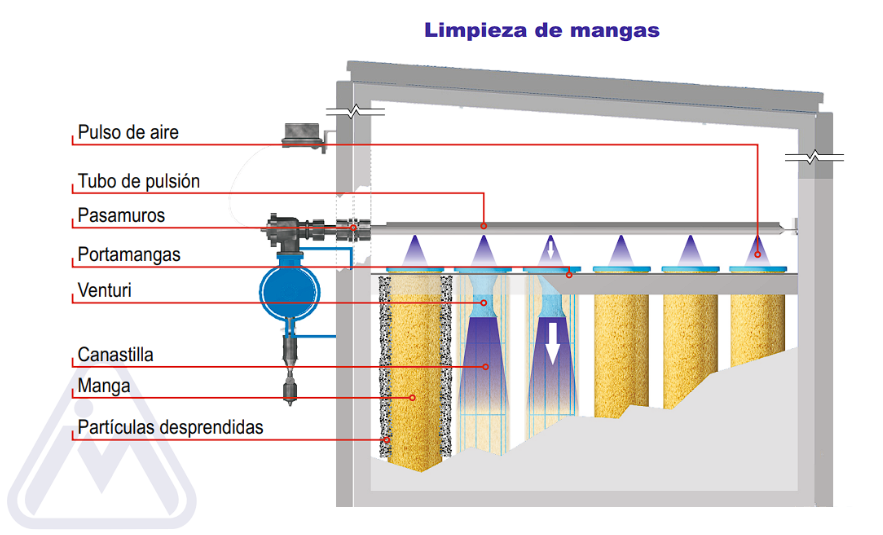

Impulse tubes

INGEMOL SA manufactures the impulse tubes in sch steel tube. 40, reinforced with

a 1” angle to increase its rigidity. These tubes are constructed using

specially developed alignments to ensure that the tube holes coincide

exactly with the center of the sleeves.

They are inserted directly into the high flow valves and are secured by a grommet

at one end, and at the other by a stud and cap nut, to facilitate

easy removal.

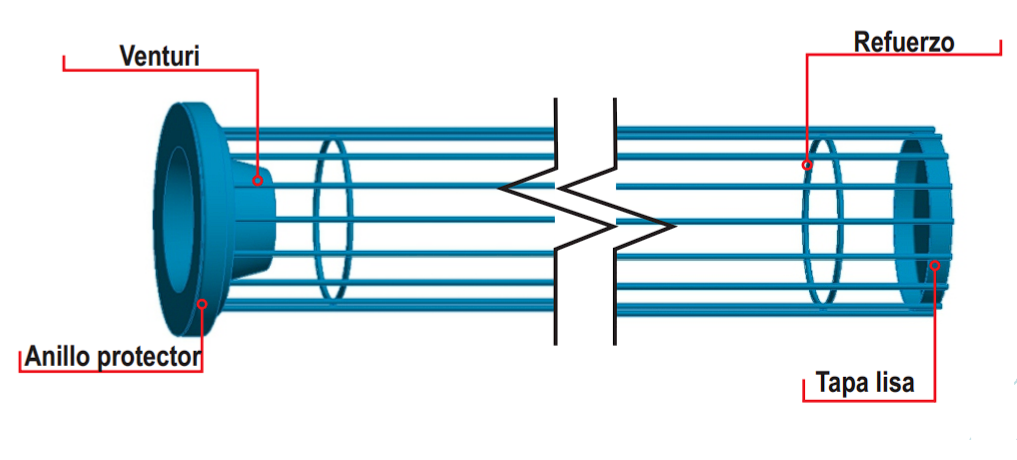

Filter bag cages

The structure of the filter bag cages shall be 16 vertical rods of 3,2 mm drawn.

Electro welded, with separators every 200 mm. in protected 304 stainless steel

with epoxidenolic paint, to withstand chemical attacks and aggressive environments.

At the top consists of a venturi at the entrance, to multiply the

cleaning air and a lip to protect the spring fixing the sleeve. On the

The bottom has a metal disc (mirror) to prevent tears in the textile.

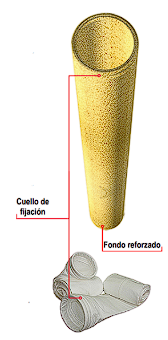

Filter Sleeves

They are bags sewn in the shape of a bag and are used to separate

dust from the air stream. They are generally made of needle felt,

with triple stitching or with temperature gluing.

The filter bags are supplied in the material selected according

to the requirements of the process to be decontaminated and in the dimensions that

are required; They are made under strict quality standards.

At the bottom they have a textile disc and a double fabric reinforcement to prevent

breakage due to friction, at the mouth they have a steel strap, which when expanded

makes a seal on the sleeve holder sheet. This is why this type of sleeves are

called self-fixing or fixing sleeves (Snap Band). The sleeve is

manufactured along its length with a triple seam, in thread of the same material.