Solutions for material handling in cement plants

Raw material dryers

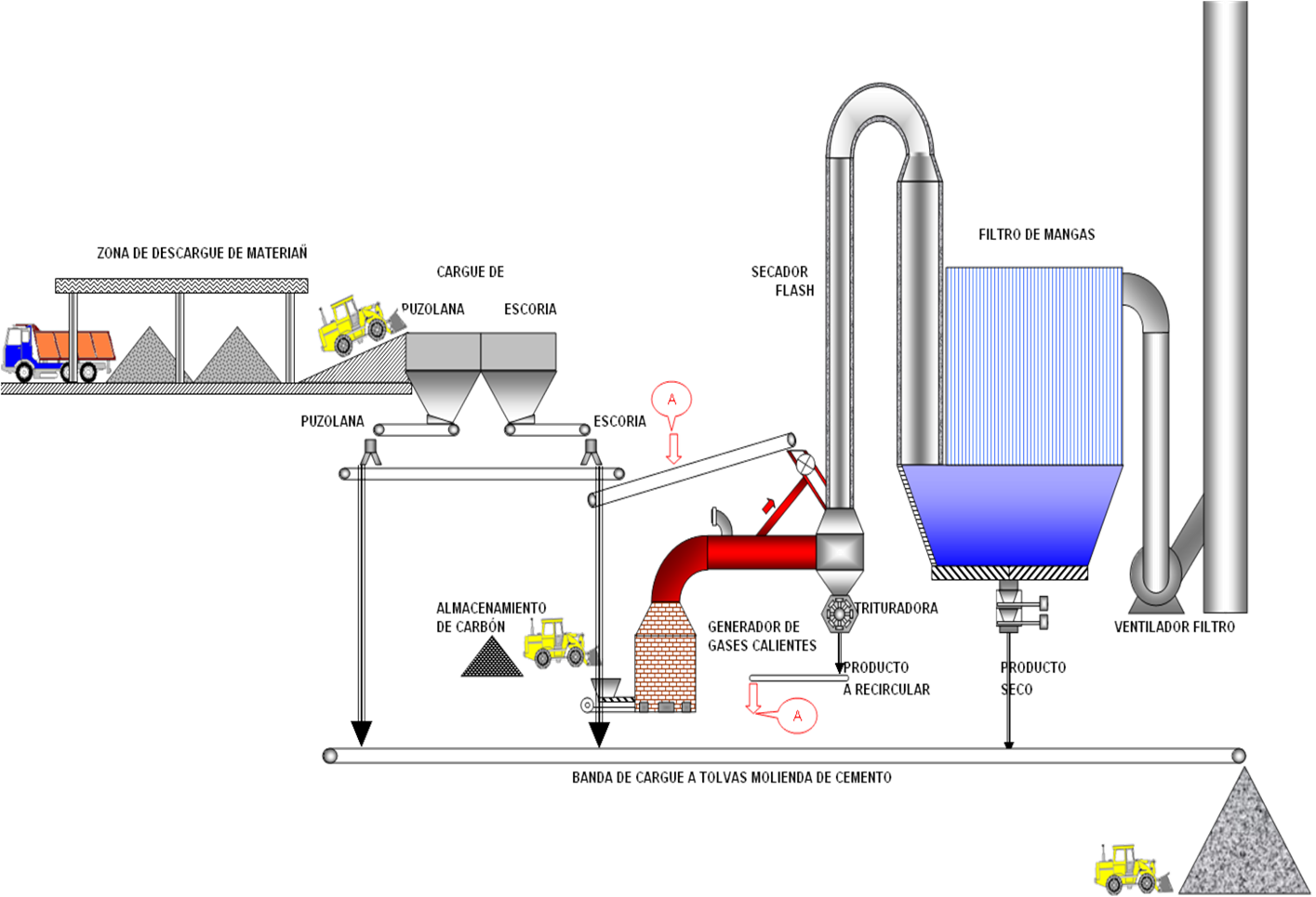

General drying scheme

Our raw material dryer solutions

Additive dryer dedusting system

Dry mortar dryer emissions control system - Cementos Tequendama

Drum dryer emission control system - Ultracem

Room pressurization

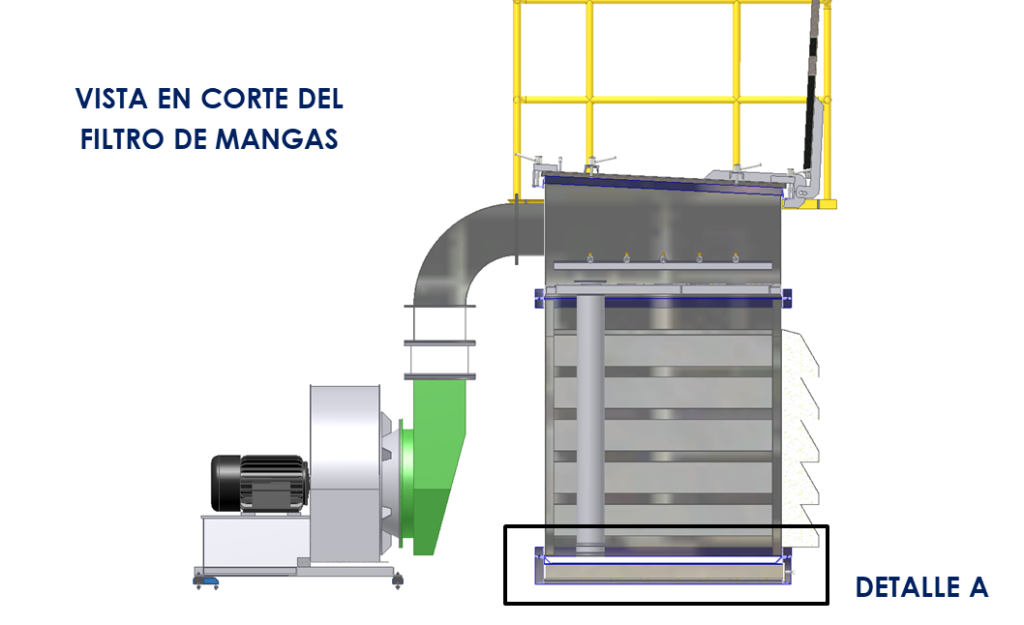

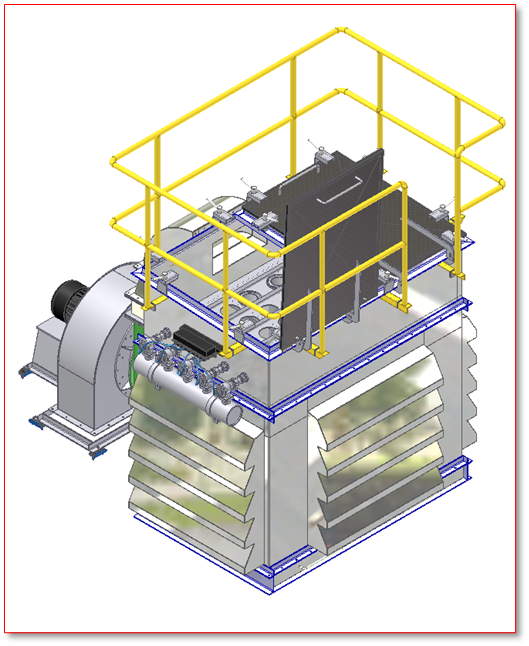

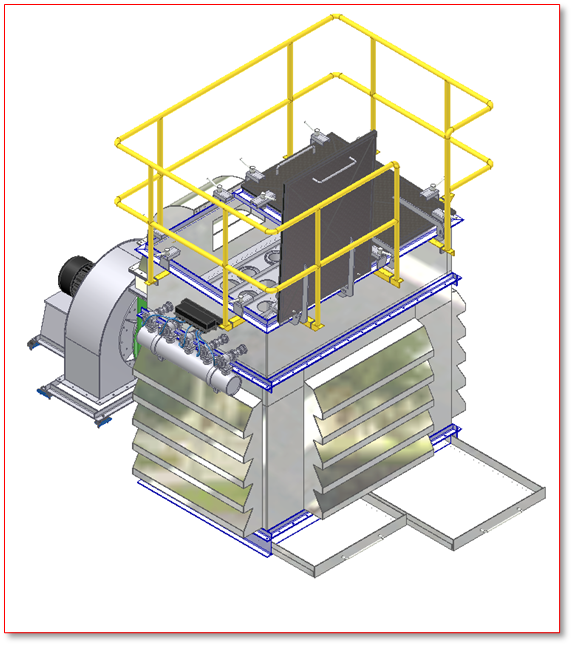

Compressor room baghouse filter trays.

The baghouse has material collection trays at the bottom, where the material captured by the baghouse is deposited.

These trays are manually extracted and then the material accumulated in them is removed. It is estimated that this operation should be carried out every 15 to 30 days.

Our solutions for room pressurization

Installation of pressurization plants for coal blower room manufactured by Ingemol.s.a. for Holcim.

Compressor room pressurization manufactured by Ingemol.s.a. for Argos - RioClaro plant.

Compressor room pressurization manufactured by Ingemol.s.a. for Argos - Nare plant.

Compressor room pressurization manufactured by Ingemol.s.a. for Argos - Sogamoso plant.

Pressurization Scheuch electrical substation manufactured by Ingemol.s.a. for Argos

Compressor room pressurization manufactured by Ingemol.s.a. for Acerías Paz del Rio.

Pressurization of furnace motor control room Holcim plant - Nobsa

Pressurization of furnace discharge motor control room - Holcim plant - Nobsa

Compressor room pressurization Ingemol.s.a. plant - Sogamoso

Air Exchangers

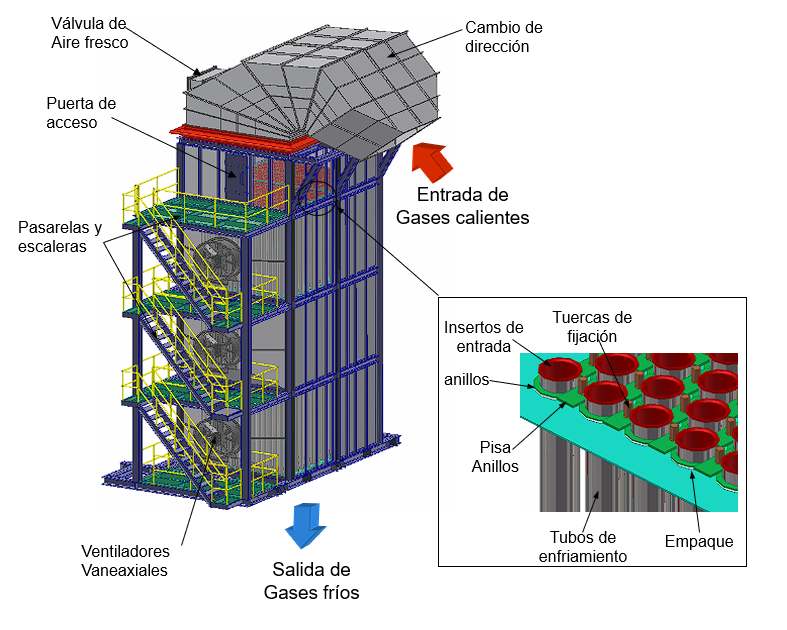

General Description

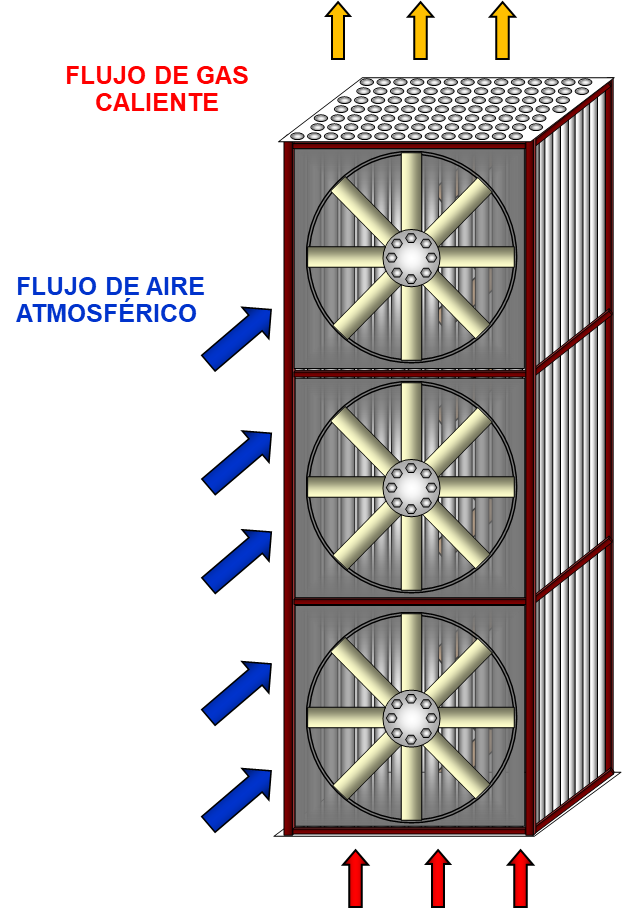

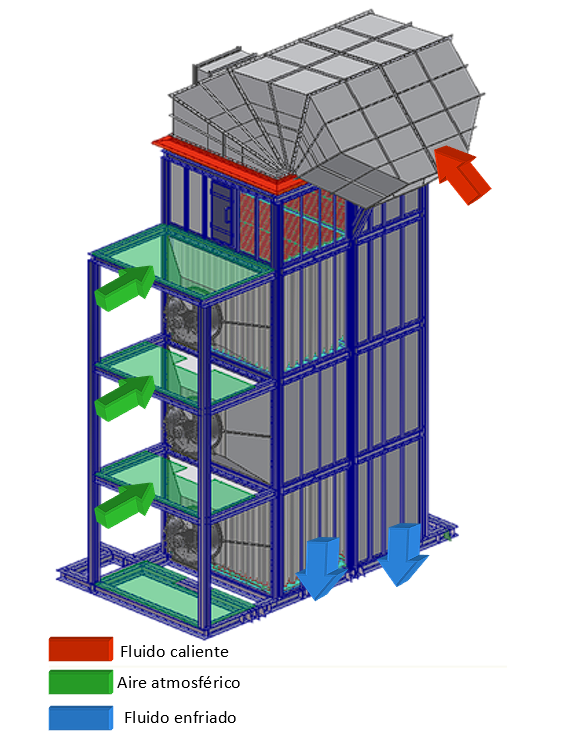

It is an equipment used for the rapid cooling of a gas stream with atmospheric air.

Its application in the cement industry is mainly for conditioning the excess air temperature before a baghouse.

Principle of operation

The hot air (temperature up to 500°C) circulates inside small diameter vertical tubes (capillaries). It is cooled by ambient air, which is blown across the heat exchange surface by a series of fans installed to cover the entire area of the tubes. The cooling air absorbs the heat before being expelled into the environment.

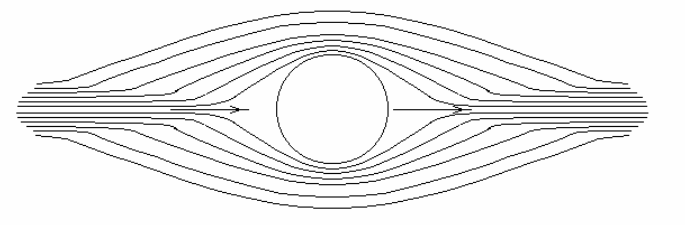

The cooled fluid hitting the tubes splits and forms a film along the surface. As the fluid passes the surface of the cylinder the fluid accelerates. The velocity reaches a maximum on both sides of the cylinder and then decreases at the rear forming a wake; the characteristics of the flow pattern depend on the fluid velocity and the outside diameter of the cylinder.

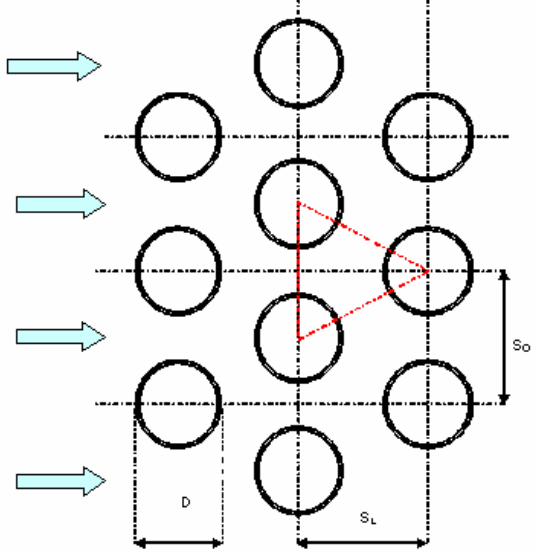

The arrangement of the tubes of our heat exchangers is of the staggered type (three rolls) because it is more efficient in heat exchange.

Tube insertion and clamping system

Tube bundle assembly procedure of an Ingemol air-to-air heat exchanger

The tube is inserted into the upper tube carrier plate, guided through the holes of the intermediate plates and inserted into the support base.

The tube is guided until it reaches the base tube carrier plate where it is supported.

At the top of the cooler, packing seals are installed on each of the cooling tubes.

The foot plates are installed and then the inserts are installed to protect the inlet of the tubes.

Axial fans forced draft coolers

The air flow for cooling is induced by means of axial fans, which, by means of a control loop, vary their speed to regulate the temperature at the outlet to the operating level required by the filter.

These fans are appropriate for high flows at low pressures.

It is composed of high efficiency profiled aluminum blades with adjustable blade angle at rest.

Our solutions for Air Exchangers

Integrated Electric Furnace Dust Removal System manufactured by Ingemol.s.a. for Acerías Paz del Rio

Cementos Tequendama 1 exchanger assembly manufactured by Ingemol.s.a. for Cementos Tequendama.

Cementos Tequendama 2 exchanger assembly manufactured by Ingemol.s.a. for Cementos Tequendama.

High efficiency integrated cyclone system manufactured by Ingemol.s.a. for Holcim.

Assembly of tubular heat exchanger manufactured by Ingemol.s.a. for Holcim.

Hood Furnace assembly manufactured by Ingemol.s.a. for Holcim.

Pre-assembly Hood oven manufactured by Ingemol.s.a. for Holcim.

Holcim 1 duct assembly manufactured by Ingemol.s.a. for Holcim.

Holcim 2 duct assembly manufactured by Ingemol.s.a. for Holcim.

High efficiency cyclones

Principle of Operation

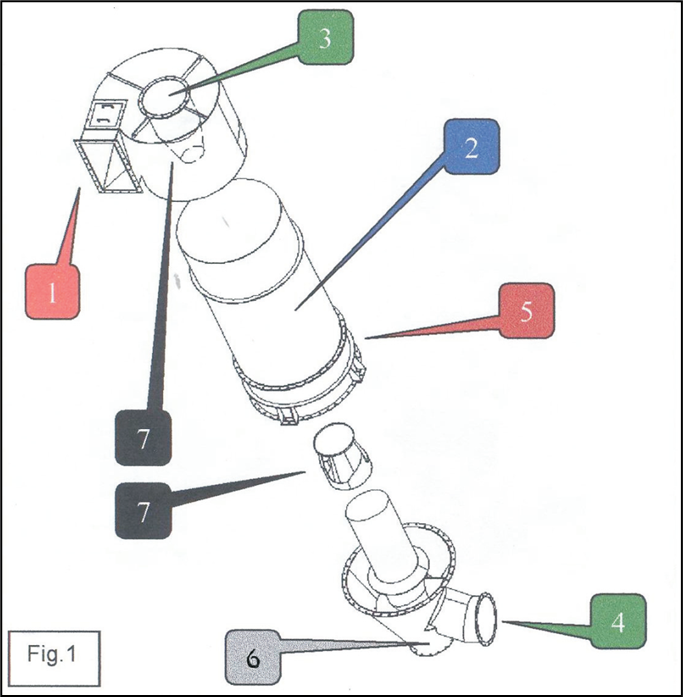

Description of components

Each high efficiency cyclone consists of: a spiral-shaped suction (1), a separation chamber (2) which is essentially cylindrical in shape, upper and lower exhaust ducts (3 and 4), a sedimentation chamber (5) with a conical dust extraction element (6) and finally steering vanes to reduce pressure loss (7).

Our solutions for high efficiency Cyclones

High Efficiency Cyclones H2 Clinker Cooler manufactured by Ingemol.s.a. for Argos Toluviejo plant.

High Efficiency Cyclones Clinker Cooler H1 manufactured by Ingemol.s.a. for Argos Toluviejo plant.

High Efficiency Cyclones Clinker Cooler H1 manufactured by Ingemol.s.a. for Argos Sogamoso plant.

High efficiency integrated cyclone system manufactured by Ingemol.s.a. for Holcim.

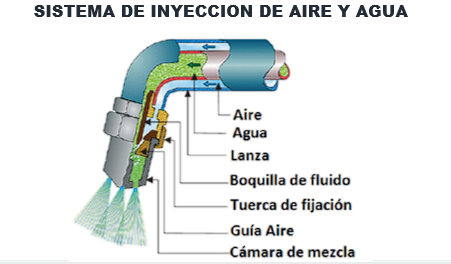

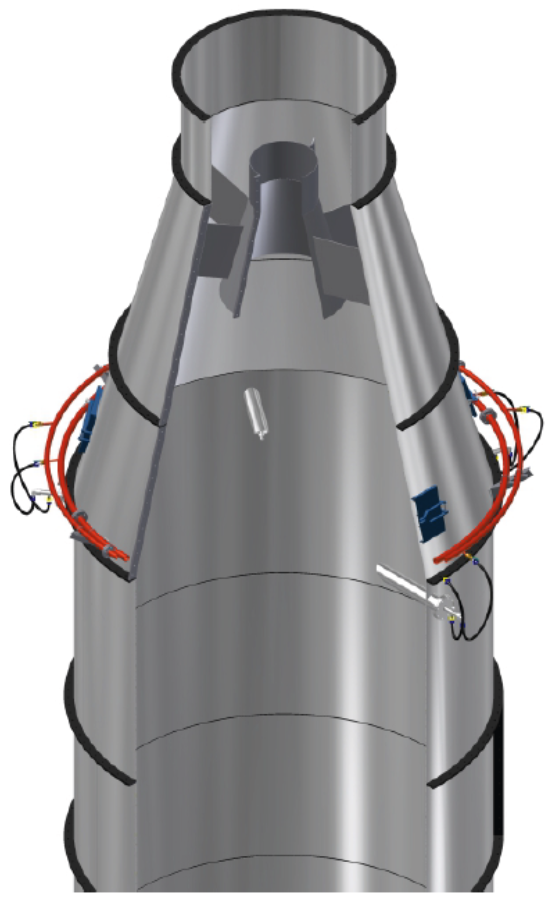

Gas conditioning system

Hot gases are conducted at low speed through the interior of a vertical cylinder. At the top of the cylinder, automated water is injected with the help of air. The water, in the form of droplets of very small diameter, evaporates instantaneously, reducing the temperature of the gases.

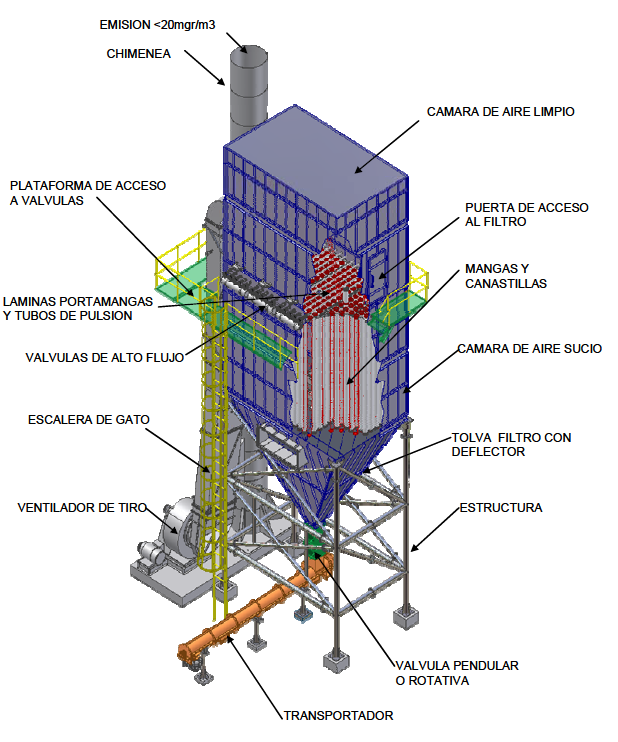

Conversions and Reforms

Ingemol designs and performs conversions or reforms to different types of particle retention systems such as electrostatic or reverse air filters, among others, which are not complying efficiently, converting them into jet-pulse bag filters and ensuring compliance with environmental standards for particulate matter emissions.

The conversions or refurbishments we perform are an economical alternative to a total change of the equipment, resulting in a high quality product that will guarantee strict compliance with environmental requirements.

These conversions consist of implementing our technology into systems designed by third parties, improving cleanliness, updating procedures, replacing parts, installing controls and instrumentation, and taking advantage of existing infrastructure.

Ingemol designs conversions to jet-pulse baghouse filters according to the equipment installed, regardless of the working conditions in which they are installed. The conversions or refurbishments that Ingemol performs usually include:}

Our solutions for the Gas Conditioning System

Furnace 1 gas cleaning system manufactured by ingemol.s.a. for Argos - Betania Plant (year 1998).

Emission Control System line 1 manufactured by ingemol.s.a. for Argos Sangil - (year 2000)

Emission Control System line 2 manufactured by ingemol.s.a. for Argos Sangil - (year 2001)

Separators

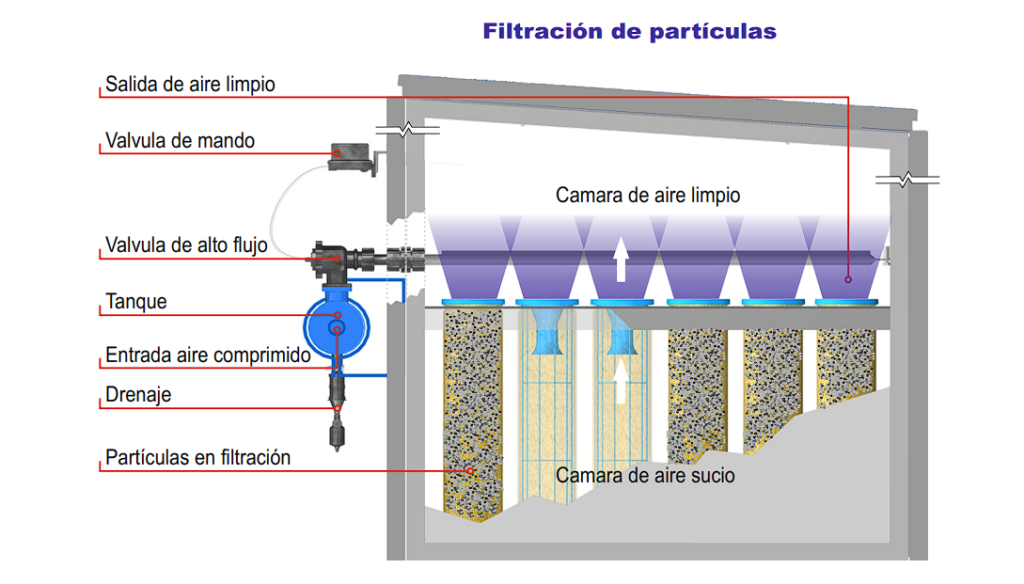

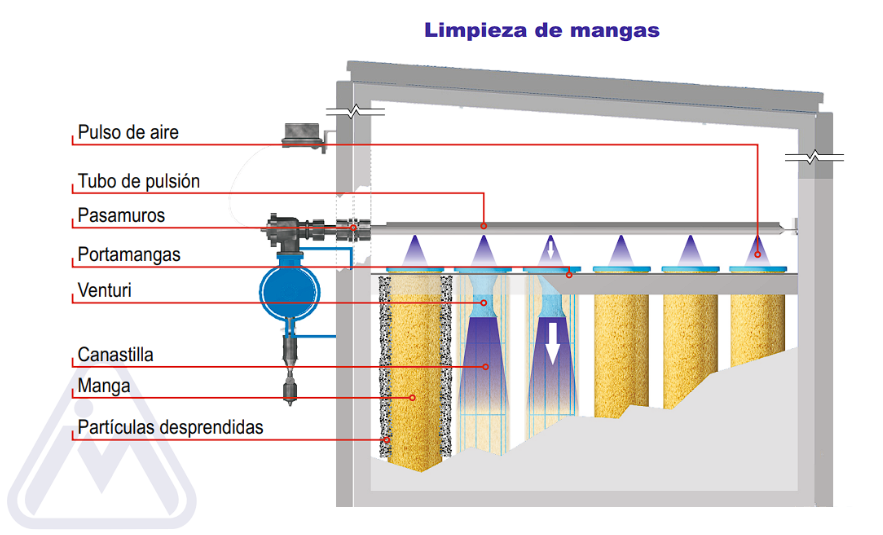

Detail of the operation inside the filter

Our mill and separator solutions

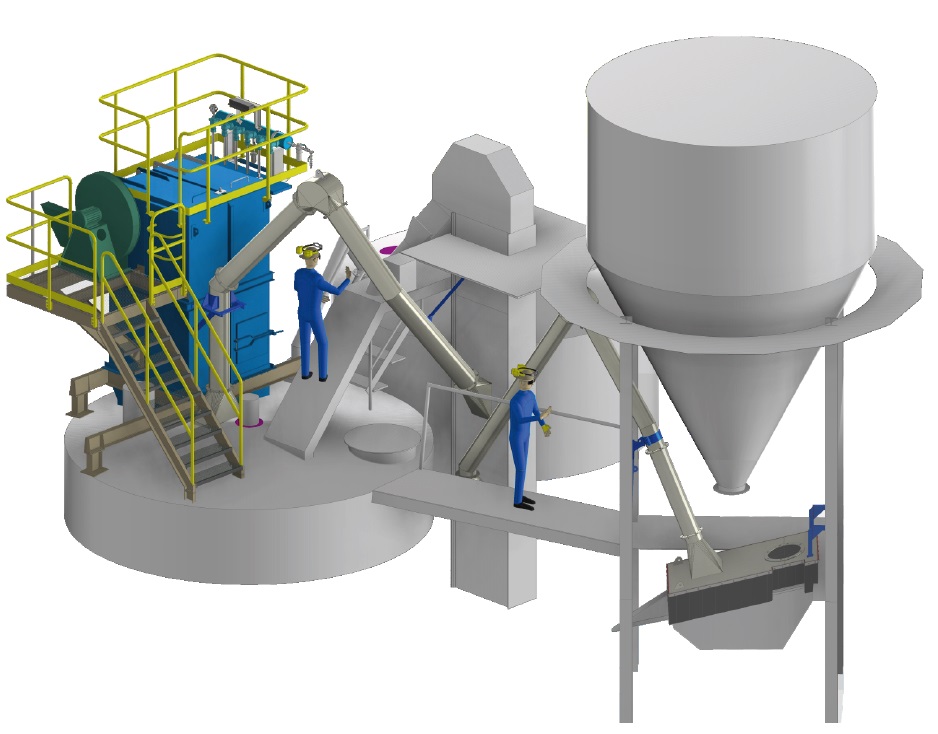

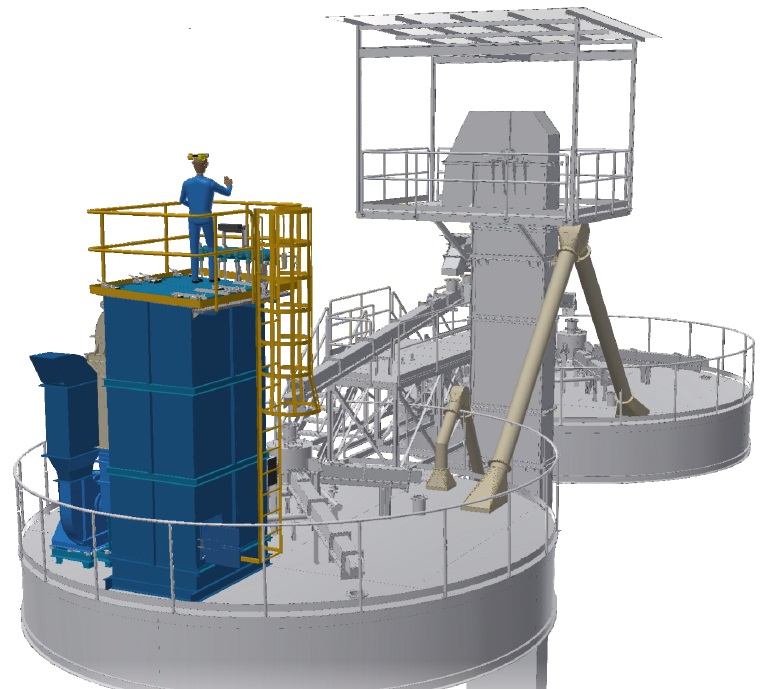

Z4 cement mill system - Argos manufactured by Ingemol.s.a. for Argos- Rioclaro plant (year 2020)

Coal Mill Filter System No. 2 - manufactured by Ingemol.s.a. for Argos - Rioclaro plant (year 2017)

Dosimats Z1 and Z3 System manufactured by Ingemol.s.a. for Argos - Rioclaro Plant (year 2010)

Cement Mill System manufactured by Ingemol.s.a. for Argos - Dominica Plant (year 2016).

Cement mill filter system 1 manufactured by Ingemol.s.a. for Argos - Sabanagrande plant.

Cement Mill Filter System 1 manufactured by Ingemol.s.a. for Argos - Sogamoso plant (year: 1996)

Cement Mill Filter System 2 manufactured by Ingemol.s.a. for Argos - Sogamoso plant (year: 1996)

Cement Mill System Installed by Ingemol.s.a. for Cementos Nacionales (year 2016)

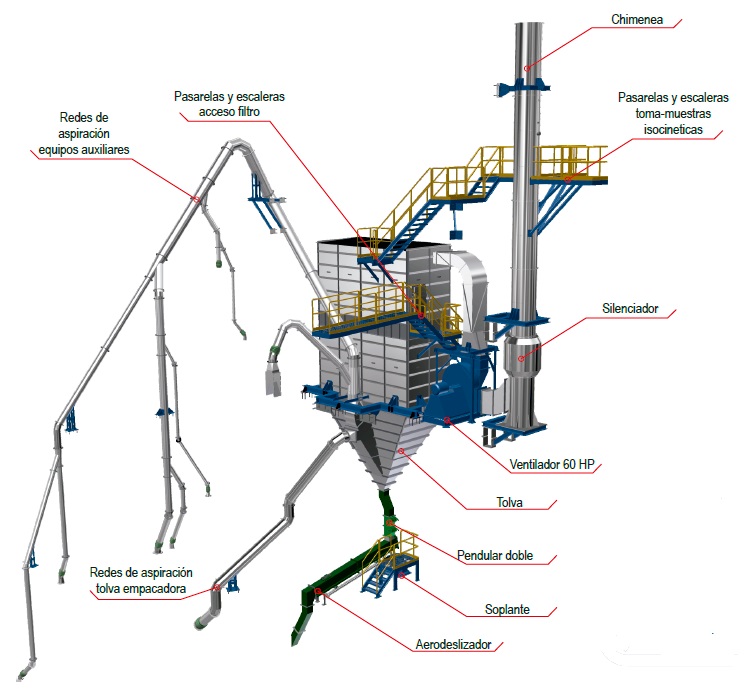

Balers

Our solutions for the control of emissions in balers

Emission control system in auxiliary balers, manufactured by Ingemol S.A. for Argos RioClaro.

Emission control system in balers manufactured by Ingemol S.A. for Argos Betania.

Emission control system in balers manufactured by Ingemol S.A. for Argos Sogamoso.

Emission control system in baling machine N°1 manufactured by Ingemol S.A. for Cementos Tequendama.

Emission control system in baler packer No. 2 manufactured by Ingemol S.A. for Cementos Tequendama.

Emissions control system at the Cementos Andinos Dominican Republic packaging plant.

Emission control system at Cementos Nacionales cement packing plants

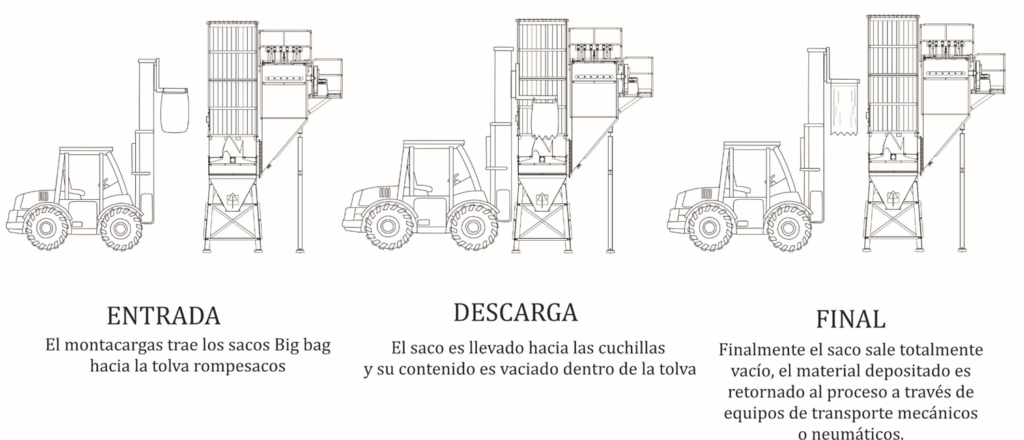

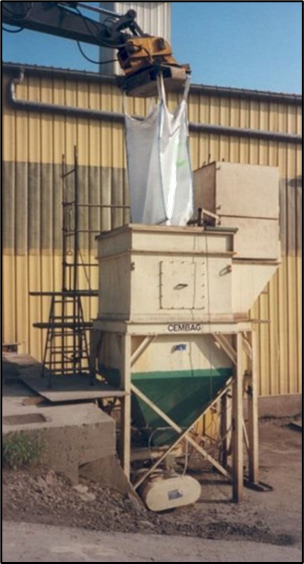

Bag Breaker Hoppers

Big Bag Emptying Procedure

Principle of Operation

Our solutions for bag-breaking hopper emission control

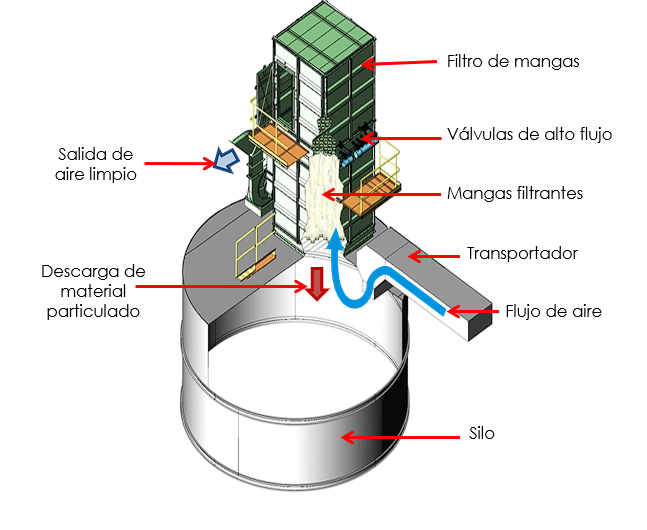

Storage Silos

The dedusting of storage silos is recommended to be done using Bin Vent type bag filters connected directly to the silo, sucking the air and discharging the material at the same point; this avoids the need to use a hopper, suction ducts and discharge valve.

Our storage silo solutions

Storage silos, pulverized coal silo manufactured by Ingemol.s.a. for Holcim Nobsa Plant.

Storage silos, alumina silo manufactured by Ingemol.s.a. for Holcim Nobsa Plant.

Storage silos, Granulated Coal silo manufactured by Ingemol.s.a. for Holcim Nobsa Plant.

Storage silos, Bauxite silo manufactured by Ingemol.s.a. for Holcim Nobsa Plant.

Storage silos, 7m³, 42m³ and 96m³ silos manufactured by Ingemol.s.a. for Argos Rioclaro Plant.

Storage silos trans. Pneumatic manufactured by Ingemol.s.a. for Argos Tolú Plant.

Storage silos trans. Pneumatic Clinker manufactured by Ingemol.s.a. for Argos Sogamoso Plant.

Storage silos trans. Slag pneumatic manufactured by Ingemol.s.a. for Argos Sogamoso Plant.

Storage silos, fine clinker silos manufactured by Ingemol.s.a. for Argos Sogamoso Plant.

Storage silos, ash silo, spark arrester silo manufactured by Ingemol.s.a. for Argos Sogamoso Plant.

Storage silos, ash silos manufactured by Ingemol.s.a. for Cementos Tequendama.

Storage silos manufactured by Ingemol.s.a. for Calidra

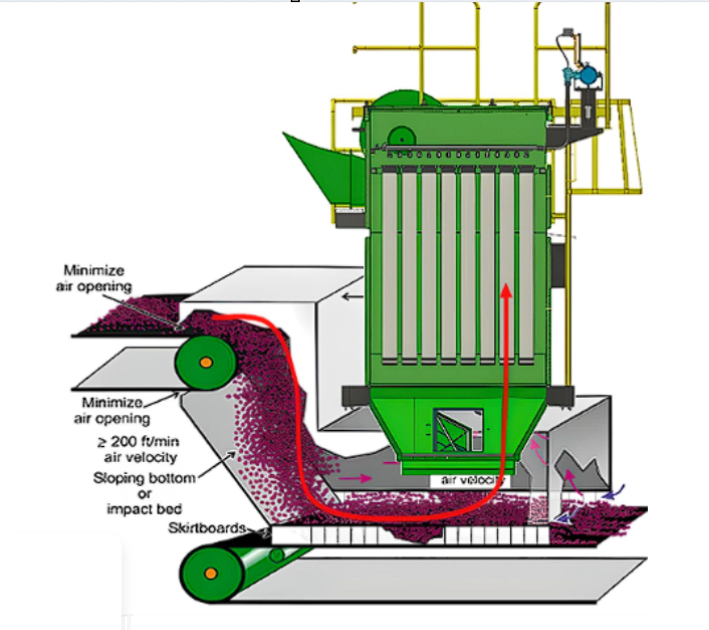

Conveyor Belts

Our Conveyor Belt Solutions

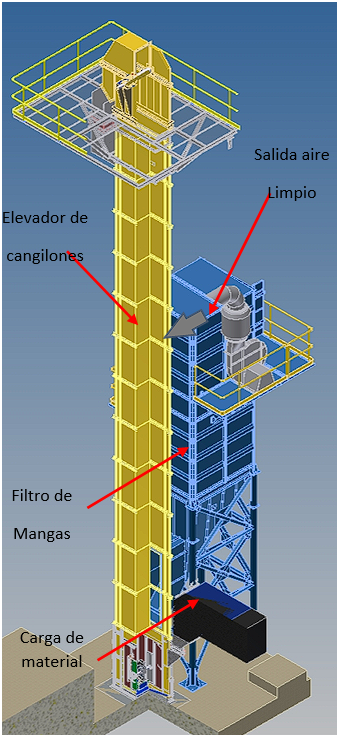

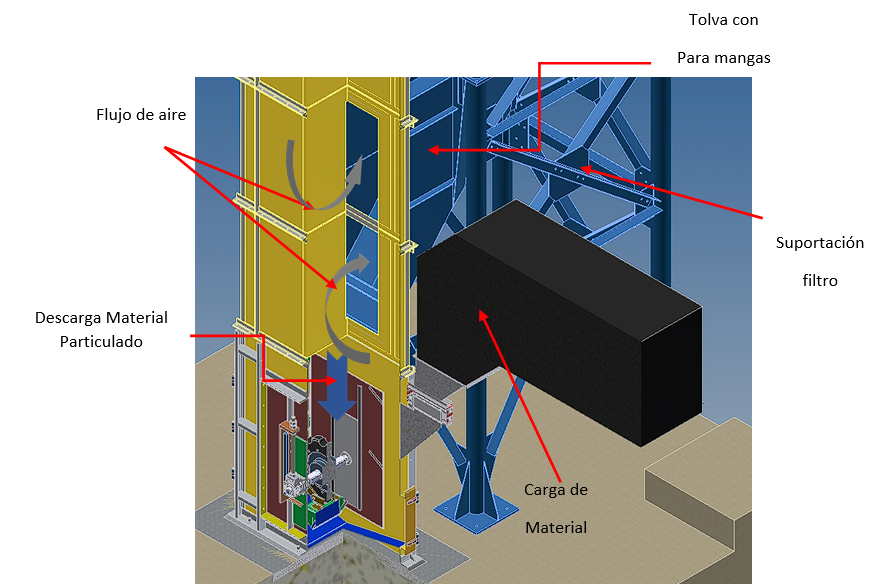

Extraction in Elevators

Our Solutions for Elevator Extraction

Fede silo elevator manufactured by Ingemol.s.a. for Cementos Tequendama (2014).

Bin Vent Aero Elevator Extraction System manufactured by Ingemol.s.a. for Cementos Tequendama.

Elevator Extraction System Elevator boot manufactured by Ingemol.s.a. for Cementos Tequendama.

Bin Vent Aero Elevator Extraction System manufactured by Ingemol.s.a. for Argos Panama.