-> Material transport systems using hovercraft

-> Dense phase pneumatic conveying system.

-> Screw conveyor conveying system

Material transport systems using hovercraft

It is also called Air Activated Conveyor or Pneumatic Gravity Conveyor. This is essentially a rectangular duct divided into an upper part (dirty chamber) and a lower part (clean chamber) by means of a 5 mm thick canvas, made of 100% polyester material, resistant to abrasion and to temperatures up to 120ºC. With an inclination of between 8 and 10º.

The material is fed through the upper part of the porous medium. Pressurized air is introduced through the lower part or clean chamber.

The air penetrates through the porous media and fluidizes the material allowing it to slide or flow and creates a continuous flow from the inlet to the outlet.

Our projects executed with hovercraft

Cement transport system using hovercraft Argos plant - Rioclaro Transport of calcined clay (2019)

Cement transport system using hovercraft at the Tequendama - Suesca plant.

Cement transport system by means of hovercraft Holcim Nobsa plant

Cement transport system using hovercraft at Argos Panama plant - Cement transport to high silos

Cement conveying system using hovercraft plant - Cementos Nacionales Sogamoso

Cement conveying system using hovercraft at the Argos Sogamoso plant

Cement transport system by means of hovercraft Holcim Nobsa plant

Cement transport system by means of hovercraft at the Sabanagrande argos plant.

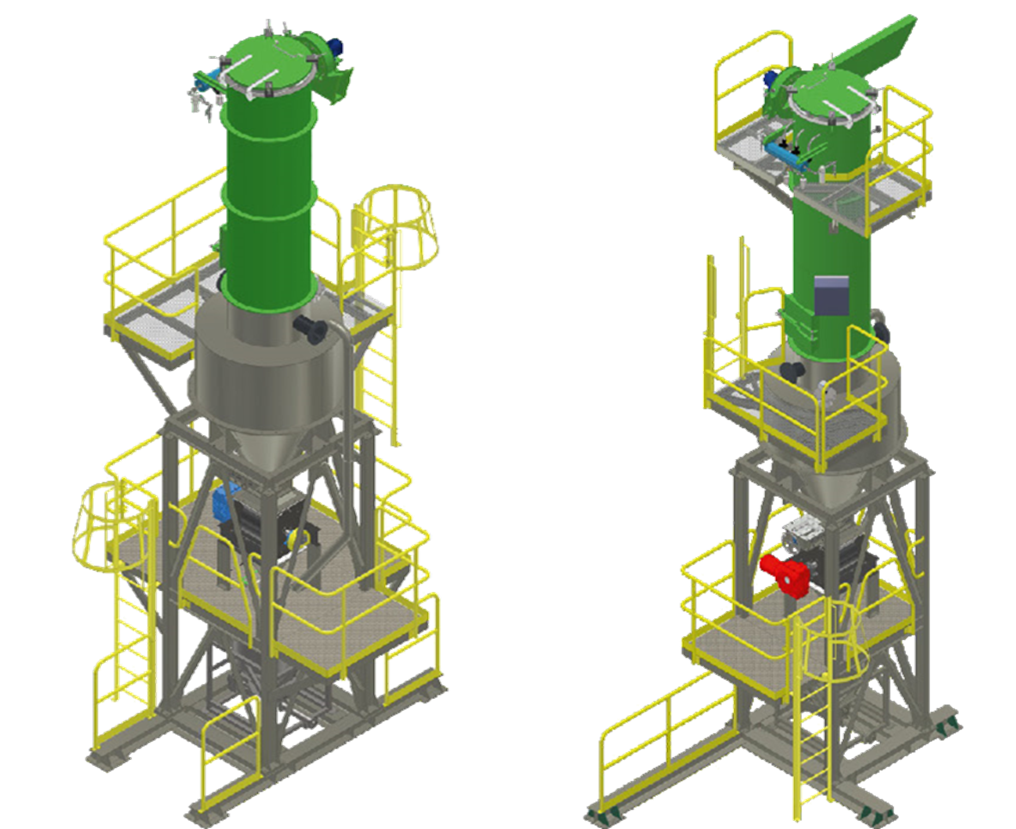

Dense phase pneumatic conveying system.

The operating principle of the dense phase pneumatic conveying system is the low conveying velocity of the material, between 2 and 12m/s. The pressure vessel is filled from the top by gravity. Once filled, the inlet valve is closed and the required compressed conveying air is applied to the inside of the vessel.

This air can come from the general supply or be generated directly by a compressor. The maximum compressed air pressure will be between 2 and 4 bar. The distribution of the compressed air to the product or by-pass is controlled and regulated by a control unit for maximum optimization. A non-return valve ensures the safety and reliability of the system. A new filling cycle of the pressure tank is started only when the emptying signal from the conveyor indicates it.

Our projects executed with dense phase pneumatic conveying.

Pneumatic conveying system for clinker fines cooler to hopper 10 m³ - Argos Sogamoso plant (2020)

Pneumatic conveying system for slag fines - Argos Sogamoso plant (2016)

Pneumatic conveying system for clinker fines - Argos Sogamoso plant (2015)

Pneumatic conveying system for clinker fines - Argos Tolú plant (2022)

Pneumatic conveying system for clinker fines - Argos Tolú plant (2018) Dilute phase.

Pneumatic conveying system for clinker fines to mc1 - Argos Tolú plant (2018).

Pneumatic conveying system for clinker fines to mc3 - Argos Tolú plant (2018).

Screw conveyor transport system

Helical Screw, worm or worm conveyor is one of the oldest and most versatile types of conveyors, designed to convey solid fluid materials and consists of a system of helical blades (helix rolled from a flat steel bar) or screw conveyor rotating inside a trough or stationary body.

The material entering the trough or body is moved along its path by the rotation of the screw which is supported by supporting bearings. Inlets, outlets, gates and other accessories control the material and its disposition.

Our projects carried out with screw conveyors

Screw conveyor transport system installed by Ingemol s.a. for Holcim Nobsa plant.

Screw conveyor transport system installed by Ingemol S.A. for Acerias Paz del Rio.

Auger conveyor system installed by Ingemol S.A. for Argos Zona Franca plant.

Screw conveyor transport system installed by Ingemol s.a. for Argos Argos Sogamoso Plant.

Auger conveyor system installed by Ingemol S.A. for Argos Haiti plant.

Screw conveyor transport system installed by Ingemol S.A. for Argos Rio Claro plant - line 4.

Auger conveyor system installed by Ingemol s.a. for Argos Rio Claro - Arcillas plant.

Screw conveyor transport system installed by Ingemol s.a. for Ultracem.

Screw conveyor transport system installed by Ingemol s.a. for Argos Rio Claro Z4 plant.

Material dosing systems

Our projects executed with dosing systems

Clinker fine dosing system to mc1 installed by Ingemol.s.a. for argos toluviejo plant - sucre.

Clinker fine dosing system to mc3 installed by Ingemol.s.a. for argos toluviejo plant - sucre.

Alumina dosing system installed by Ingemol.s.a. for Holcim plant Nobsa - Boyacá.

Ckd fines dosing system installed by Ingemol.s.a. for Holcim Nobsa - Boyacá plant.

Ash dosing system installed by Ingemol.s.a. for cementos Tequendama - Suesca Cundinamarca

Clinker fines dosing system installed by Ingemol.s.a. for Argos Sogamoso - Boyacá plant.

Bauxite dosing system installed by Ingemol.s.a. for Holcim plant Nobsa - Boyacá.